Modular Concrete Batching Plant

Price 1400000 INR/ Piece

Modular Concrete Batching Plant Specification

- Product Type

- Concrete Batching Plant

- General Use

- MS

- Material

- Other

- Type

- Modular

- Weight (kg)

- 1 to 20 Tonne

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC based fully automatic

- Power Source

- Electric

- Power Consumption

- 60 - 85 kW

- Storage Capacity

- 4 x 40 m

- Hopper Capacity

- 4 x 5 m

- Hopper Quantity

- 4

- Conveyor Capacity

- 200 tons per hour

- Mixing Drum Speed

- 20 rpm

- Discharging Height

- 4.1 m

- Voltage

- 380 V

- Dimension (L*W*H)

- 18200 x 8200 x 18500 mm

- Feature

- Easy installation, Compact design, High performance

- Color

- Customized

- Control Cabin

- Provided

- Water Pump Power

- 2.2 kW

- Batching Method

- Load cell based

- Water Weighing Accuracy

- ±1%

- Mixer Type

- Twin shaft mixer

- Admixture Weighing Accuracy

- ±1%

- Output Capacity

- 60 to 120 m³/h

- Aggregate Batching Accuracy

- ±2%

- Mixing Cycle Time

- 60 seconds

- Frame

- Heavy-duty steel

- Cement Weighing Accuracy

- ±1%

- Aggregate Storage Bins

- 4

- Foundation

- Minimal, modular setup

- Operating Temperature

- -10°C to +45°C

Modular Concrete Batching Plant Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 3 Units Per Week

- Delivery Time

- 15 Days

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- Main Domestic Market

- All India

- Certifications

- CE, ISO

About Modular Concrete Batching Plant

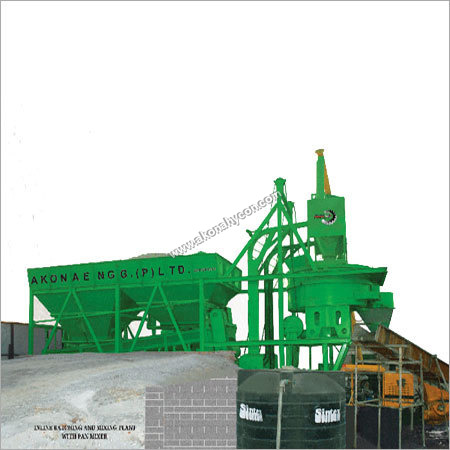

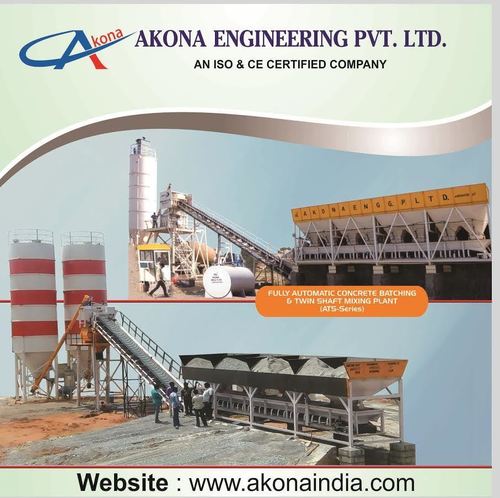

We are a significant name of the industry involved in manufacturing, supplying and exporting fine finish Modular Concrete Batching Plant. All the plants are fabricated using high-grade metals which we source from trustworthy vendors of the market. These plants are used in various construction sites for mixing large amount of concrete materials. The batching plants offered by us are checked on strict quality parameters so that only fine finish machines get delivered at clients premises. In addition to this, Modular Concrete Batching Plant we offer is fitted with pneumatic wheels that helps in its easy movement from one place to other.Modular Concrete Batching Plant Features:

- Longer functional life

- Optimum functioning

- Corrosion resistant nature

- Easy installation

Superior Performance and Precision

Our modular batching plant stands out with aggregate batching accuracy of 2%% and cement, water, and admixture weighing accuracy of 1%%. The PLC-based fully automatic control system ensures smooth operations, while load cell-based batching enhances consistency. This combination guarantees reliable concrete quality for your projects, contributing to consistent and safe structures.

Versatile and Modular Design

With a compact footprint of 18200 x 8200 x 18500 mm, this concrete batching plant is perfect for projects requiring rapid assembly and mobility. Its modular design minimizes foundation needs, allowing flexible relocation and setup on varying sites. Four aggregate bins with ample storage make it suitable for diverse batching requirements.

Advanced Automation and User Convenience

Designed for seamless operation, the plant features a dedicated control cabin, computerized automation, and a user-friendly PLC interface. Operators enjoy real-time data visibility and process control, while the automatic system manages dosing and mixing cycles, maximizing productivity and reducing the risk of operator errors.

FAQs of Modular Concrete Batching Plant:

Q: How is the Modular Concrete Batching Plant installed on-site?

A: Installation is straightforward due to its modular design, requiring only minimal foundation work. The heavy-duty steel frame and prefabricated modules allow for quick assembly and easy relocation, making it ideal for projects needing fast setup.Q: What are the primary benefits of using a twin shaft mixer in this plant?

A: The twin shaft mixer ensures thorough, uniform mixing within a 60-second cycle time. It handles large volumes efficiently, producing high-quality concrete for demanding projects, and is well-suited for consistent output in continuous operations.Q: When is this batching plant best utilized?

A: This plant is suitable for medium to large-scale construction projects where high output (60120 m/h) and rapid, consistent batching are essential. Its broad operating temperature range also enables year-round use.Q: Where can this batching plant be effectively deployed?

A: Thanks to its compact, modular design and minimal foundation requirements, the plant can be deployed on various construction sites, including remote or urban locations in India and international markets seeking fast, reliable concrete supply.Q: What control system is implemented for plant operation?

A: Operations are managed through a PLC-based fully automatic control system, accessed from a dedicated cabin. This system oversees accurate batching, mixing, and discharge, with computerized supervision for optimal efficiency and error reduction.Q: How does the batching process ensure material measurement accuracy?

A: Material batching employs advanced load cell technology, delivering aggregate accuracy of 2%% and cement, water, and admixture accuracy of 1%%. This precision ensures consistent concrete quality throughout each batch.Q: What are the advantages of the plants aggregate storage capacity?

A: Four aggregate storage bins, each with a capacity of 40 m and hoppers of 5 m each, enable efficient storing and handling of different materials. This arrangement minimizes downtime for refilling and supports uninterrupted large-scale production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Concrete Batching Plant Category

Concrete Batching Plant With Drum Mixer

Price 280000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Concrete Mixing Plant, Mobile Concrete Batching Plant

Material : Cast Iron

Computerized : Yes

Storage Capacity : 20000 50000 Kilogram(Kg)

Twin Shaft Batch Mixer

Price 1400000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Other, Industrial Mixer

Material : Other

Computerized : Yes

Storage Capacity : 500 to 2000 L

Fully Automatic Concrete Batching Plant

Price 1400000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Other, Fully Automatic

Material : Other

Computerized : Yes

Storage Capacity : 50 Tons

Concrete Batching Twin-Shaft Mixing Plant

Price 1400000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Other, Mixing Plant

Material : Other

Computerized : Yes

Storage Capacity : 50200 Tons

Send Inquiry

Send Inquiry