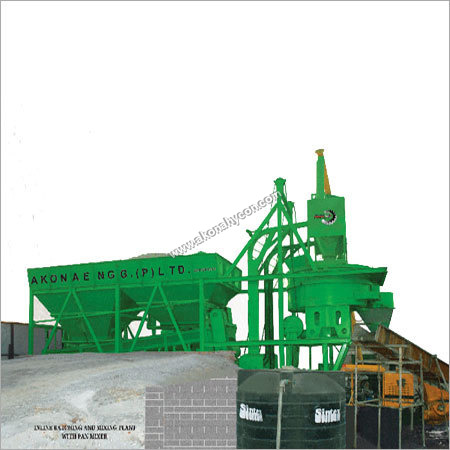

Pan Mixer Type Batching Plant

Price 1400000 INR/ Unit

Pan Mixer Type Batching Plant Specification

- Product Type

- Pan Mixer

- General Use

- Construction

- Material

- Other

- Type

- Batching Plant

- Weight (kg)

- 1 to 20 Tonne

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Based

- Power Source

- Electric

- Power Consumption

- 5 - 15 kW (approx.)

- Storage Capacity

- 500 to 1000 liters

- Hopper Capacity

- 500 liters

- Hopper Quantity

- Single

- Conveyor Capacity

- 30 to 60 TPH

- Mixing Drum Speed

- 20 rpm

- Discharging Height

- 1500 mm

- Voltage

- 415 V

- Dimension (L*W*H)

- 4000*1750*2250 mm

- Feature

- Compact & High Mixing Efficiency

- Color

- Yellow & Blue

- Aggregate Feeding

- Manual/Semi-Automatic

- Safety

- Overload & Short Circuit Protection

- Application

- Ready Mix Concrete, Precast

- Mixing Blades

- High Wear Resistance

- Mixer Liner

- Replaceable Steel Plates

- Batch Cycle Time

- 60 seconds

- Operating Temperature

- -10C to +55C

- Electrical Panel

- Weatherproof

- Output Capacity

- 15 to 30 m/hr

- Sensor

- Digital Weighing Sensor

- Chassis

- Heavy Duty Fabricated Steel

- Operation Mode

- Manual/Automatic

- Water Pump

- 1 HP (Heavy Duty)

- Noise Level

- 85 dB

Pan Mixer Type Batching Plant Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 3 Units Per Week

- Delivery Time

- 15 Days

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- Main Domestic Market

- All India

- Certifications

- CE, ISO

About Pan Mixer Type Batching Plant

Since the day of our inception, we have been successfully manufacturing, supplying and exporting Pan Mixer Type Batching Plant. All the offered products are designed in accordance with international quality standards and norms, using high-grade raw material and other components. We also have a team of expert quality controllers, which checks and tests Batching Plant Pan Mixer Type on different parameters to ensure flawlessness.

Batching Plant Pan Mixer Type

AP series is dedicated to concrete batching and mixing plant with pan mixer. This is the economical series having the benefits of Pan mixing technology. Low poluting fast mixing and low noise are the basic features that makes it special. These Plants are available in two models: AP-45 (Output 45 M3/hr) and AP-30 ( Output 30M3/hr)

Technical Data

| Model | AP-30 | AP-45 |

| Capacity (CUM / Hr) | 30 | 45 |

| GEO. Volume (cum) | 1.7 | 2.5 |

| RMC Out Put / Batch | 0.5M3 | 0.75M3 |

| %% of Filling | 40%% | 40%% |

| Batches Per Hour | 60 | 60 |

| Discharge Height From G.L | Discharge In T.M. | Discharge In T.M. |

| Capacity (8 Hours) | 240 M3 | 360 M3 |

| Boom Scrapper | In Built | In-Built |

| Discharge Gate Opening SystemH | Hydraulic | Hydraulic |

| Power Cosumption | ||

| Pan Motor | 25 HP | 35 HP |

| Skip motor | 10 HP | 15 HP |

| Screw Feeder Motor | 10 HP | 15 HP |

| Scrapper Motor | 10 HP | 10 HP |

| Water Pump | 2x5 HP | 2x5 HP |

| Compressor Motor | 5 HP | 5 HP |

| Chemical Motor | 1 HP | 1 HP |

| Vibrator's | 2 x 1 HP | 2 x 1 HP |

| Power Pack Motor | 2 HP | 2 HP |

| Net Consumption | 75 HP | 95 HP |

| Power Supply | 415 x 3 x 50 Hz | 415 x 3 x 50 Hz |

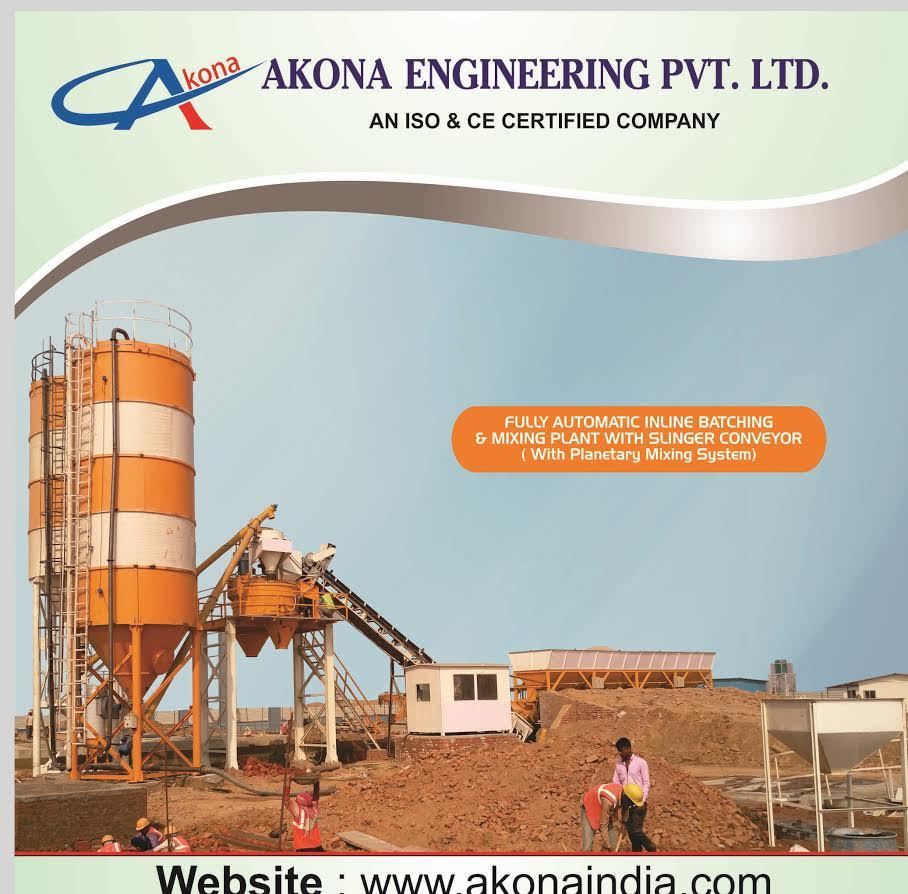

Technical Features:

1) PLC operated completely automatic control panel.

2) Blade mixing technology with planetary gear boxes.

3) Electronic weighing system for better accuracy in design mix.

4) Separate weighing system for cement and fly ash.

5) Italian screw feeder, to pour cement speedily.

6) Password locking facility.

7) Water and ad-mix pour by weight.

8) Boom scrapper to make you work easier.

9) Pneumatically operated gate for aggregate and sand.

10) Italian vibrators.

11) Tubulated print out system for each batch.

12) No pit required only nominal civil work.

13) Heat proof control cabin.

14) Cement silo with vertical screw feeder (optional).

15) Hydraulic discharge system.

16) E-mail and SMS facility (Optional).

Advanced Mixing Efficiency and Output

With a 60-second batch cycle, high wear-resistant mixing blades, and a 20 rpm drum speed, the Pan Mixer Type Batching Plant delivers consistent, high-quality concrete batches. Its output capacity of 15 to 30 m/hr suits both ready-mix and precast applications, while the compact design and hopper capacities streamline site logistics.

Robust Safety and Control Features

This batching plant prioritizes operator safety and operational reliability. Overload and short circuit protection, coupled with a digital weighing sensor and PLC-based control system, ensures precise, secure operation. The weatherproof electrical panel further maintains system safety and functionality in varying environmental conditions.

Customizable Operation and Application

Users can switch between manual and automatic operation, benefitting from flexibility on-site. Aggregate feeding can be managed manually or semi-automatically, catering to different workforce skills or project requirements. The units heavy-duty steel construction and replaceable liners prolong lifespan and simplify maintenance.

FAQs of Pan Mixer Type Batching Plant:

Q: How does the Pan Mixer Type Batching Plant enhance concrete mixing efficiency?

A: The plant utilizes a 60-second batch cycle, high wear-resistant mixing blades, and replaceable steel liners within a compact drum rotating at 20 rpm. These features ensure homogeneous mixing, minimized downtime, and consistent concrete quality, benefiting both ready-mix and precast applications.Q: What operational modes are available for this batching plant?

A: Operators can choose between manual and automatic modes, managed through a PLC-based computerized control system. This flexibility allows the plant to adapt to varying project needs, workforce capabilities, and levels of automation required on-site.Q: When should the mixer liner plates and mixing blades be replaced?

A: Mixer liner plates and blades are made with high wear-resistant materials but should be inspected regularly, especially in high-output operations. Replacement is recommended once signs of significant wear or reduction in mixing performance are observed to guarantee concrete quality and prolong equipment life.Q: Where is the best environment to install and operate this batching plant?

A: The plant is engineered to perform optimally in construction environments across India, with an operating temperature range of -10C to +55C. Its weatherproof electrical panel enables both indoor and outdoor installations, ensuring reliability in diverse climatic conditions.Q: What process does the batching plant use for aggregate feeding and weighing?

A: Aggregate feeding can be performed manually or semi-automatically. The plant employs a digital weighing sensor for precise measurement, reducing errors and ensuring the correct proportions for each batch, essential for maintaining quality standards in ready-mix and precast concrete.Q: What are the primary benefits of using this batching plant in construction projects?

A: Key benefits include rapid batching cycles, high mixing homogeneity, robust safety features, customizable operation modes, and reduced maintenance thanks to replaceable components. Its compact design and energy efficiency (5-15 kW power consumption) further optimize resource use in small to medium construction sites.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Concrete Batching Plant Category

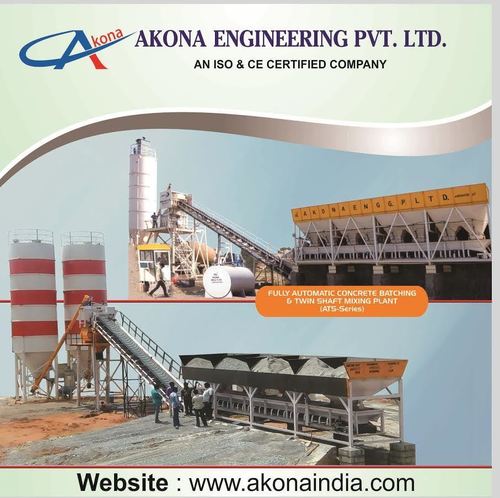

Twin Shaft Batch Mixer

Price 1400000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Power Consumption : 15 kW

Weight (kg) : 1 to 20 Tonne

Power Source : Electric

Type : Other, Industrial Mixer

Fully Automatic Concrete Batching Plant

Price 1400000 INR / Unit

Minimum Order Quantity : 1 Unit

Power Consumption : 75 kW

Weight (kg) : 1 to 20 Tonne

Power Source : Electric

Type : Other, Fully Automatic

Concrete Batching Twin-Shaft Mixing Plant

Price 1400000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Power Consumption : 60120 kW

Weight (kg) : 1 to 20 Tonne

Power Source : Electric

Type : Other, Mixing Plant

Mobile Concrete Batching Plant

Price 1400000 INR / Unit

Minimum Order Quantity : 1 Unit

Power Consumption : 6080 kW

Weight (kg) : 1 to 20 Tonne

Power Source : Electric

Type : Other, Batching Plant

Send Inquiry

Send Inquiry