| Model | AP-30 | AP-45 |

| Capacity (Cum Hr) | 30 | 45 |

| Geo. Volume (Cum) | 1.7 | 2.5 |

| RMC out put /Batch | 0.5 M3 | 0.75 M3 |

| %% of Filling | 40.00%% | 40.00%% |

| Batches Per Hour | 60 | 60 |

| Discharge Height From G.L | Discharge in TM | Discharge in TM |

| Capacity ( 8 Hours) | 240 M3 | 360 M3 |

| Boom Scrapper | In Built | In Built |

| Discharge Gate Opening System | Hydraulic | Hydraulic |

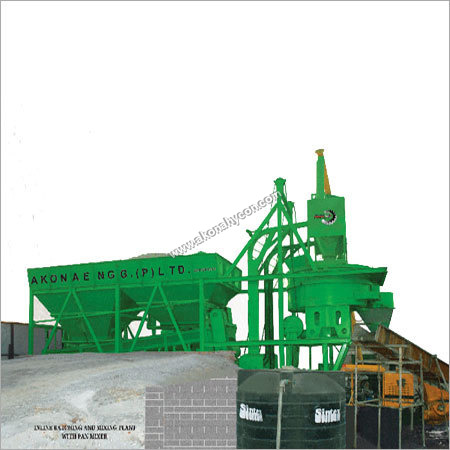

Batching and Mixing Plant

Price 1400000 INR/ Unit

Batching and Mixing Plant Specification

- Product Type

- Concrete Batching Plant

- General Use

- Construction

- Material

- Other

- Type

- Automatic

- Weight (kg)

- 1 to 20 Tonne

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Based

- Power Source

- Electric

- Power Consumption

- 20 kW

- Storage Capacity

- 30 m

- Hopper Capacity

- 600 L

- Hopper Quantity

- 4

- Conveyor Capacity

- 120 TPH

- Mixing Drum Speed

- 20 rpm

- Discharging Height

- 4.1 m

- Voltage

- 415 V

- Dimension (L*W*H)

- 12000 x 3200 x 15000 mm

- Color

- Yellow

- Mixer Type

- Twin Shaft

- Vibration System

- Fitted

- Dust Collecting System

- Available

- Batch Time

- 60 seconds

- Water Pump Capacity

- 2 HP

- Chassis Type

- Heavy Duty

- Aggregate Size

- Up to 40 mm

- Loader

- Available

- Cycle Time

- 1 Minute

- Operating Temperature

- -10°C to +50°C

Batching and Mixing Plant Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 3 Units Per Week

- Delivery Time

- 15 Days

- Main Export Market(s)

- Australia, South America, Western Europe, Middle East, Africa, Central America, Asia, Eastern Europe, North America

- Main Domestic Market

- All India

- Certifications

- CE, ISO

About Batching and Mixing Plant

We are one of the accredited manufacturers, suppliers and exporters of genuine quality Batching and Mixing Plant. All these plants are designed and developed employing Pan mixing technology. Offered range of plants is available to customers in varied models such as AP-45(Output 45m3/Hr) and AP-30 (Output 30m3/Hr). In addition to this, Batching and Mixing Plant offered by us is accredited in the market for its excellent attributes such as:

- Automatic functioning

- Locking facility available

- Low noise operation

- Heat proof

Technical Specification:

Power Consumption :

| Model | AP-30 | AP-45 |

| Pan Motor | 30 HP | 40 HP |

| Skip Motor | 10 HP | 15 HP |

| Screw Feeder Motor | 10 HP | 15 HP |

| Scrapper Motor | 10 HP | 15 HP |

| Water Pump | 2 x 5 HP | 2x5 HP |

| Compressor Motor | 5 HP | 5 HP |

| Chemical Motor | 1HP | 1HP |

| Vibrators | 2 x 1 HP | 2 x 1 HP |

| Power Pack Motor | 3 HP | 3 HP |

| Power Supply | 415 x 30 x 50 Hz | 415 x 30 x 50 Hz |

| Recommended DG Set | 110 KVA | 125 KVA |

1) PLC operated completely automatic control panel.

2) Blade mixing technology with planetary gear-boxes.

3) Electronic weighing system for better accuracy in design, mix.

4) Separate weighing system for cement and fly-ash.

5) Italian screw feeder, to pour cement speedily

6) Password locking facility

7) Water and ad-mix pour by weight.

8) Boom scrapper to make you work easier.

9) Pneumatically weighing system for cement and fly-ash.

10) Italian vibrators.

11) Tabulated print out system for each batch.

12) No pit required only nominal civil work.

13) Heat proof control cabin.

14) Cement silo with vertical screw feeder (optional)

15) Hydraulic discharge system.

16) E-mail or SMS facility (optional)

Advanced Mixing Efficiency

The twin shaft mixer is designed for rapid and thorough blending of aggregates, water, and cement. With a 60-second batch time and a mixing drum speed of 20 rpm, the plant produces homogeneous concrete consistently, critical for structural durability and reliability in construction.

Automated Control and Safety

Featuring a computerized, PLC-based control system, this plant promotes seamless and precise operation. The comprehensive automation reduces manual intervention, improving consistency and safety while supporting operators with easy-to-use digital controls and monitoring.

Robust Engineering for Versatile Use

With a heavy-duty chassis and temperature resilience (-10C to +50C), the plant adapts efficiently to varying environmental conditions and project scales. Its strong construction and dust collecting system make it suitable for complex sites, harnessing stable performance in demanding construction sectors.

FAQs of Batching and Mixing Plant:

Q: How does the twin shaft mixer enhance concrete quality in batching plants?

A: The twin shaft mixer achieves superior concrete consistency by thoroughly blending materials within a 60-second batch cycle. Its design handles aggregate sizes up to 40 mm and operates at a speed of 20 rpm, reducing segregation and ensuring homogeneous mixes for improved structural strength.Q: What is the purpose of the fitted vibration system in the plant?

A: The integrated vibration system assists in efficient material movement, preventing bridging or clumping in hoppers and the mixing drum. This technology ensures continuous and accurate batching, enhancing productivity and mix uniformity.Q: When is it optimal to use this batching and mixing plant?

A: This plant is ideal for large-scale construction projects requiring frequent and high-volume concrete production. Its one-minute cycle time and automatic controls maximize output during peak construction phases while maintaining consistent quality.Q: Where can this batching and mixing plant be installed?

A: The robust chassis and tolerances for operating temperatures from -10C to +50C allow installation on various construction sites, including urban infrastructure and remote areas across India, accommodating challenging field conditions with reliable output.Q: What processes are automated in this mixing plant system?

A: Key processes such as material batching, water dosing, mixing, discharging, and quality control are fully automated via the computerized PLC control system. This streamlines workflow, reduces human error, and boosts efficiency.Q: How does the dust collecting system benefit the operational environment?

A: The dust collecting system minimizes airborne particulates during operation, promoting a safer and cleaner worksite. This feature supports compliance with environmental standards and protects equipment longevity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Concrete Batching Plant Category

Fully Automatic Concrete Batching Plant

Price 1400000 INR / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : 1 to 20 Tonne

Material : Other

Computerized : Yes

Type : Other, Fully Automatic

Twin Shaft Batch Mixer

Price 1400000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : 1 to 20 Tonne

Material : Other

Computerized : Yes

Type : Other, Industrial Mixer

Pan Mixer Type Batching Plant

Price 1400000 INR / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : 1 to 20 Tonne

Material : Other

Computerized : Yes

Type : Other, Batching Plant

Modular Concrete Batching Plant

Price 1400000 INR / Piece

Minimum Order Quantity : 1 Unit

Weight (kg) : 1 to 20 Tonne

Material : Other

Computerized : Yes

Type : Other, Modular

Send Inquiry

Send Inquiry