Fully Automatic Concrete Batching Plant

Price 1400000 INR/ Unit

Fully Automatic Concrete Batching Plant Specification

- Product Type

- Concrete Batching Plant

- General Use

- Construction

- Material

- Other

- Type

- Fully Automatic

- Weight (kg)

- 1 to 20 Tonne

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Based Control Panel

- Power Source

- Electric

- Power Consumption

- 75 kW

- Storage Capacity

- 50 Tons

- Hopper Capacity

- 1200 Liters

- Hopper Quantity

- 4

- Conveyor Capacity

- 120 Tons/hour

- Mixing Drum Speed

- 23 rpm

- Discharging Height

- 4.2 m

- Voltage

- 415V

- Dimension (L*W*H)

- 13200 x 2500 x 4000 mm

- Feature

- High Precision Batching, Easy Operation, Robust Design

- Color

- Industrial Yellow

- Aggregate Storage Bins

- 4

- Admixture Dosing System

- Included

- Mixer Type

- Twin Shaft

- Supported Concrete Grade

- Up to M60

- Foundation Requirement

- Standard RCC

- Air Compressor

- 5.5 kW

- Vibrator Motors

- High Efficiency

- Aggregate Weighing Accuracy

- ±1%

- Output Capacity

- 30 m³/h

- Operating Temperature Range

- -10°C to +50°C

- Lubrication System

- Automatic

- Water Tank Capacity

- 5000 Liters

- Batch Cycle Time

- 60 seconds

- Cement Weighing System

- Digital Load Cell Based

Fully Automatic Concrete Batching Plant Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 3 Units Per Week

- Delivery Time

- 15 Days

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- Main Domestic Market

- All India

- Certifications

- CE, ISO

About Fully Automatic Concrete Batching Plant

Leveraging on our years of experience and in-depth knowledge, we are capable of manufacturing, supplying and exporting Fully automatic Concrete Batching Plant. All the offered products are designed and manufactured using quality material to ensure that final output meets with international quality standards. Furthermore, we thoroughly check our fully auto Concrete Batching Plant on certain well-define parameters to ensure flawlessness.Features:

- Longer functional life

- Sturdy construction

- Low maintenance

Technical Specification :

Model AHP-20 AHP-30 Mixer Unit PAN MIXER PAN MIXER Geometrical Volume 1.0 M3 1.7 M3 Rmc Out Put /Batch 0.35 M3 0.5 M3 Filling Percentage 35 %% 35%% Batches/Hour 60 60 Discharge Height Discharge in Pump Discharge in Pump Capacity (8 Hour) 160 M3 240 M3 Number Of Cycles/Hr 60 60 Cement Batching By weight By weight Aggregate Batching By weight By weight Water Batching By weight By weight Ad-Mix Batching By weight By weight Number Of Compartment 03 Nos. - 2/4 04 Nos. - 3/4 Size 2200mmX11500mm 2200mmX11500mm

Power Consumption :

Model AHP-20 AHP-30 Mixer Motor 20 HP 30HP Belt Conveyor Motor 7.5 HP 10 HP Cement Screw Feeder 10 HP 10 HP Water Pump 03 HP 03 HP Compressor Motor 03 HP 03 HP Vibrator Motor 0.5 HP 0.5 HP Chemical Motor 1.0 HP 1.0 HP Power Supply 415 X 50 Hz 415 X 50 Hz Net Consumption 45 HP 57.5 HP Recommended Dg Set 62 KVA or above 75 KVA or above

Precision and Productivity for Complex Projects

Experience unmatched batching accuracy with a digital load cell-based cement weighing system and 1%% aggregate weighing precision. A 60-second batch cycle, 50-ton storage, and 30 m/h output enable rapid onsite concrete production, enhancing project timelines and reducing labor overhead. This plant combines intelligent automation and rugged construction, suitable for demanding construction environments.

User-Friendly Operation and Maintenance

This batching plant employs a PLC-based control system for hassle-free automated operation, ensuring minimal manual intervention. The high-efficiency twin shaft mixer and automatic lubrication system further streamline maintenance, while the robust RCC foundation requirement adds to long-term stability. Designed with ergonomic access and a simple interface, operators benefit from reliable performance in varying climates.

FAQs of Fully Automatic Concrete Batching Plant:

Q: How does the digital load cell-based cement weighing system improve batching accuracy?

A: The digital load cell-based cement weighing system delivers precise measurement of cement quantities, minimizing human error and ensuring consistent batch quality. This technology enables the plant to achieve high-precision batching, which is crucial for maintaining required concrete strengths up to grade M60.Q: What is the typical process for operating the fully automatic batching plant?

A: Operation involves starting the automated sequence via the PLC-based control panel. Aggregates, cement, water, and admixtures are weighed and discharged into the twin shaft mixer. After a 60-second mixing cycle, the homogenous concrete is discharged at a height of 4.2 meters, ready for use. Automatic lubrication and dosing systems further simplify the process.Q: When is it best to use this batching plant in construction projects?

A: This plant is ideal for medium to large-scale projects requiring high output and precision, such as commercial buildings, bridges, and infrastructure developments. Its capability to produce up to M60 grade concrete with consistent quality makes it suitable throughout the project lifecycle, especially when rapid and reliable supply is needed.Q: Where is the Fully Automatic Concrete Batching Plant typically installed?

A: The batching plant is commonly installed onsite at construction projects or set up in concrete supply yards. It requires a standard RCC (reinforced cement concrete) foundation and can operate efficiently in both urban and remote construction locations across India.Q: What benefits does the high-efficiency twin shaft mixer provide?

A: The twin shaft mixer ensures rapid and thorough mixing of all ingredients, achieving a uniform concrete mix within each 60-second cycle. This results in higher quality concrete, reduced mixing times, and improved overall productivity for your project.Q: How does the computerized control system enhance plant operations?

A: The advanced PLC-based control panel automates the entire batching process, allowing for easy parameter adjustments and real-time performance monitoring. This leads to higher efficiency, reduced operator error, and seamless integration with modern construction workflows.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Concrete Batching Plant Category

Pan Mixer Type Batching Plant

Price 1400000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Other, Batching Plant

Product Type : Pan Mixer

General Use : Construction

Material : Other

Modular Concrete Batching Plant

Price 1400000 INR / Piece

Minimum Order Quantity : 1 Unit

Type : Other, Modular

Product Type : Concrete Batching Plant

General Use : MS

Material : Other

Twin Shaft Batch Mixer

Price 1400000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Other, Industrial Mixer

Product Type : Twin Shaft Batch Mixer

General Use : MS

Material : Other

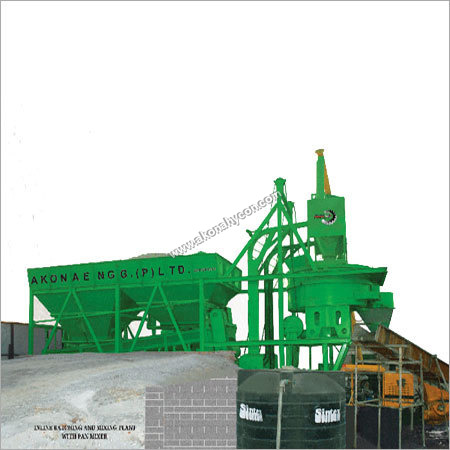

Inline Series Batching And Mixing Plant

Price 1400000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Other, Inline Series Batching and Mixing Plant

Product Type : Batching Plant

General Use : MS

Material : Other

Send Inquiry

Send Inquiry