Twin Shaft Batch Mixer

Price 1400000.00 INR/ Unit

Twin Shaft Batch Mixer Specification

- Product Type

- Twin Shaft Batch Mixer

- General Use

- MS

- Material

- Other

- Type

- Industrial Mixer

- Weight (kg)

- 1 to 20 Tonne

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Based

- Power Source

- Electric

- Power Consumption

- 15 kW

- Storage Capacity

- 500 to 2000 L

- Hopper Capacity

- 500 L

- Hopper Quantity

- 2

- Conveyor Capacity

- 60 TPH

- Mixing Drum Speed

- 30 rpm

- Discharging Height

- 2.5 m

- Voltage

- 415 V

- Dimension (L*W*H)

- 4200*1300*1800 mm

- Feature

- High Mixing Efficiency, Uniform Mixing, Durable Construction

- Color

- Grey

- Discharge Mode

- Pneumatic Discharging Gate

- Application

- Concrete Mixing, Ready Mix Plants

- Mixer Configuration

- Twin Horizontal Shaft

- Body Material

- Mild Steel (MS)

- Lubrication System

- Centralized

- Service Support

- Available

- Mixing Time

- 30 - 60 seconds per batch

- Noise Level

- < 85 dB

- Installation

- On-site

- Drive Mechanism

- Motor with Gearbox

- Aggregate Size (Max.)

- 80 mm

Twin Shaft Batch Mixer Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 3 Units Per Week

- Delivery Time

- 15 Days

- Main Export Market(s)

- Western Europe, Australia, North America, South America, Eastern Europe, Middle East, Asia, Central America, Africa

- Main Domestic Market

- All India

- Certifications

- CE, ISO

About Twin Shaft Batch Mixer

Attributes:

- Robust construction

- Less maintenance

- Longer service life

Specification

| Control System | PLC |

| Discharge System | Hydraulic |

| Operation | Automatic |

| Material | Stainless Steel |

| Capacity | 120 m3/Hr And Above |

| Brand | AKONA |

| Model/Type | TS Series |

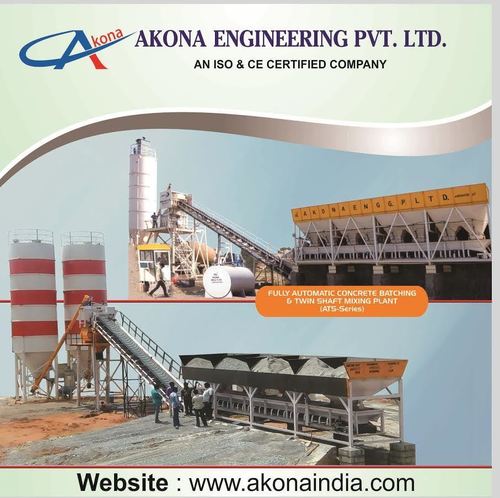

Superior Mixer Configuration

Designed with twin horizontal shafts and a mild steel body, the mixer ensures durability and long operational life. Its construction supports high-volume, rapid mixing for industrial use, making it well-suited for ready-mix concrete plants and similar demanding environments.

Automated Precision Control

The integrated PLC-based control system enables automatic and precise mixing operations. Computerized controls optimize batch consistency while reducing manual intervention, supporting large-scale, continuous production needs.

Efficient and Reliable Performance

With a mixing time of just 30 to 60 seconds per batch and a high conveyor capacity, this mixer maximizes productivity. The pneumatic discharging gate and centralized lubrication system further enhance operational efficiency and minimize downtime.

FAQs of Twin Shaft Batch Mixer:

Q: How does the Twin Shaft Batch Mixer ensure uniform concrete mixing?

A: The mixers twin horizontal shafts create a powerful interlacing movement, facilitating thorough mixing of materials. This configuration allows aggregates up to 80 mm to achieve consistent blending in each batch within 30-60 seconds, resulting in a uniform mix ideal for ready-mix plants.Q: What is the process for discharging mixed concrete from the mixer?

A: Discharging is managed by a pneumatic gate that opens automatically under PLC control. This mechanism allows for quick, efficient release of the mixed batch, minimizing manual labor and ensuring timely operations during continuous production cycles.Q: When should maintenance be performed on the mixers lubrication system?

A: The centralized lubrication system is designed for easy regular maintenance. Lubricant levels should be checked periodically according to the manufacturers service schedule typically after every major production cycle or as indicated by the PLC systems prompts.Q: Where is the Twin Shaft Batch Mixer installed, and what support is available?

A: Installation is performed on-site by trained technicians, ensuring correct setup and commissioning. Comprehensive service support is available throughout India, covering maintenance, troubleshooting, and operator training to optimize lifetime performance.Q: What applications are best suited for this mixer configuration?

A: The Twin Shaft Batch Mixer is ideal for concrete mixing, ready-mix plant operations, and industrial batch processes requiring uniform blending of materials. Its robust design and large capacity cater to demanding applications within the construction and manufacturing sectors.Q: How does the computerized control system benefit mixer operation?

A: The PLC-based control system automates key mixer functions, including batching, mixing time, and discharge. This ensures batch-to-batch consistency, reduces human error, and allows for scalable, high-volume production with minimal manual intervention.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Concrete Batching Plant Category

Concrete Batching Twin-Shaft Mixing Plant

Price 1400000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Concrete Batching TwinShaft

Power Consumption : 60120 kW

Power Source : Electric

General Use : MS

Modular Concrete Batching Plant

Price 1400000 INR / Piece

Minimum Order Quantity : 1 Unit

Product Type : Concrete Batching Plant

Power Consumption : 60 85 kW

Power Source : Electric

General Use : MS

Batching and Mixing Plant

Price 1400000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Concrete Batching Plant

Power Consumption : 20 kW

Power Source : Electric

General Use : Construction

Inline Series Batching And Mixing Plant

Price 1400000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Batching Plant

Power Consumption : 4060 kW

Power Source : Electric

General Use : MS

Send Inquiry

Send Inquiry