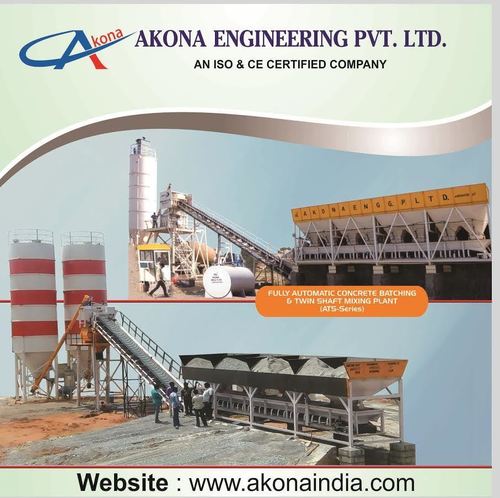

Concrete Batching Twin-Shaft Mixing Plant

Price 1400000.00 INR/ Unit

Concrete Batching Twin-Shaft Mixing Plant Specification

- Product Type

- Concrete Batching Twin-Shaft

- General Use

- MS

- Material

- Other

- Type

- Mixing Plant

- Weight (kg)

- 1 to 20 Tonne

- Computerized

- Yes

- Automatic

- Fully Automatic

- Control System

- PLC Based

- Power Source

- Electric

- Power Consumption

- 60-120 kW

- Storage Capacity

- 50-200 Tons

- Hopper Capacity

- 0.5-2 m

- Hopper Quantity

- 3-4

- Conveyor Capacity

- 150-300 Tons/Hr

- Mixing Drum Speed

- 20-25 RPM

- Discharging Height

- 4.1 m

- Voltage

- 380 V

- Dimension (L*W*H)

- 12000*2300*4150 mm

- Feature

- High Mixing Efficiency, Robust Construction

- Color

- Blue & White

- Cement Weighing System

- Electronic Load Cell

- Suitable for

- Ready-mix, Precast Applications

- Additional Product Specifications

- Operating Ambient Temperature

- -10°C to +45°C

- Control Panel Protection

- IP65

- Mixing Motor Power

- 2 x 30 kW

- Air Compressor

- Integrated, 3 HP

- Safety Features

- Emergency Stop, Protective Guard Rails

- Water Tank Capacity

- 400 Liters

- Aggregate Bin Type

- Inline

- Mixer Type

- Twin Shaft Horizontal

- Plant Output Capacity

- 60 - 120 m³/hr

- Aggregate Feeding

- Belt Conveyor

- Batch Cycle Time

- 60 Seconds

- Aggregate Weighing Accuracy

- ±2%

- Chassis Structure

- Heavy Duty Steel

- Admixture Dosing System

- Digital

Concrete Batching Twin-Shaft Mixing Plant Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 3 Units Per Week

- Delivery Time

- 15 Days

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, Africa

- Main Domestic Market

- All India

- Certifications

- CE, ISO

About Concrete Batching Twin-Shaft Mixing Plant

Owing to technologically advanced manufacturing facilities, we manufacture, supply and export genuine quality Concrete Batching and Twin-Shaft Mixing Plant. These plants are designed and developed using optimum quality metals in compliance with industry laid guidelines. All the plants are checked on strict quality parameters so that only fine finish products get delivered at customers' location. In addition to this, the Concrete Batching and Twin-Shaft Mixing Plant we offer is fitted with water pumps and air compressors for its optimum functioning.

Technical Specification :

| Chassis | Single |

| Operation | Automatic |

| Material | Stainless Steel |

| Finishing Type | Paint Coated |

| Power Source | Electric Engine |

| Model/Type | Pan Drum |

| Brand/Make | AKONA |

- PLC operated completely automatic control panel.

- Blade mixing technology with planetary gear-boxes.

- Electronic weighing system for better accuracy in design, mix.

- Separate weighing system for cement and fly-ash.

- Italian screw feeder, to pour cement speedily

- Password locking facility

- Water and ad-mix pour by weight.

- Imported Twin Shaft mixer.

- Pneumatically operated gate for aggregate & sand.

- Italian vibrators.

- Tabulated print out system for each batch.

- No pit required only nominal civil work.

- Heat proof control cabin.

- Cement silo with vertical screw feeder (optional)

- Hydraulic discharge system.

Superior Mixing Efficiency

With its twin-shaft horizontal mixer and a batch cycle time of only 60 seconds, this plant achieves thorough, homogeneous mixing. The electronic load cell cement weighing, digital admixture dosing, and belt conveyor aggregate feeding guarantee precise proportions and reliable results for every batch, supporting both ready-mix and precast requirements.

Robust and Reliable Construction

Built on a heavy-duty steel chassis and equipped with protective guard rails, this mixing plant is designed to withstand tough operating conditions. Integrated safety features including emergency stop and IP65 control panel protection ensure safe, uninterrupted operation even in challenging environments.

Advanced Automation and Control

The PLC-based control system enables fully automatic operation, optimizing plant output capacity between 60 to 120 m/hr. Computerized settings enhance process stability, facilitate monitoring, and reduce human error, ensuring consistent delivery for large-scale projects with minimal operator intervention.

FAQs of Concrete Batching Twin-Shaft Mixing Plant:

Q: How accurate is the aggregate weighing system in the Twin-Shaft Mixing Plant?

A: The aggregate weighing system utilizes electronic load cells and offers an accuracy of 2%%, ensuring precise proportioning for every batch and improving overall mix quality.Q: What process does the plant use for aggregate feeding and cement weighing?

A: Aggregates are fed using a belt conveyor, while cement is weighed through an electronic load cell system, providing both efficient transfer and high measurement consistency for optimal batching.Q: Where can the Twin-Shaft Mixing Plant be installed, and what ambient temperatures is it suitable for?

A: This mixing plant can be deployed at ready-mix and precast concrete production sites across India, and is engineered to operate reliably in ambient temperatures ranging from -10C to +45C.Q: When should an operator use the emergency stop feature, and how does it enhance safety?

A: The emergency stop should be activated if there is a risk to personnel or equipment. It immediately halts all operations, acting as a critical safety measure alongside protective guard rails and the IP65-rated control panel.Q: What is the benefit of the digital admixture dosing system?

A: The digital admixture dosing system provides precise control over chemicals added during batching, enhancing concrete performance, durability, and quality consistency in every mix.Q: How does the automatic PLC control system improve plant productivity?

A: The PLC-based control system automates batching processes, reduces human error, and maintains steady output rates between 60 and 120 m/hr, thereby improving workflow efficiency and supporting continuous production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Concrete Batching Plant Category

Twin Shaft Batch Mixer

Price 1400000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Power Source : Electric

Mixing Drum Speed : 30 rpm

Voltage : 415 V

Control System : Other, PLC Based

Modular Concrete Batching Plant

Price 1400000 INR / Piece

Minimum Order Quantity : 1 Unit

Power Source : Electric

Mixing Drum Speed : 20 rpm

Voltage : 380 V

Control System : Other, PLC based fully automatic

Pan Mixer Type Batching Plant

Price 1400000 INR / Unit

Minimum Order Quantity : 1 Unit

Power Source : Electric

Mixing Drum Speed : 20 rpm

Voltage : 415 V

Control System : Other, PLC Based

Inline Series Batching And Mixing Plant

Price 1400000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Power Source : Electric

Mixing Drum Speed : 20 rpm

Voltage : 415 V

Control System : Other, PLC based automatic control panel

Send Inquiry

Send Inquiry