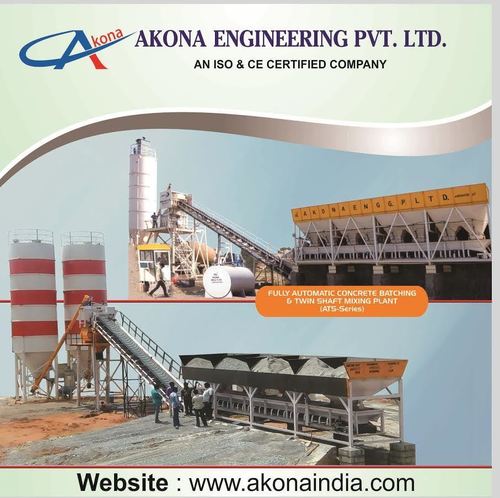

Inline Series Batching And Mixing Plant

Price 1400000.00 INR/ Unit

Inline Series Batching And Mixing Plant Specification

- Product Type

- Batching Plant

- General Use

- MS

- Material

- Other

- Type

- Inline Series Batching and Mixing Plant

- Weight (kg)

- 1 to 20 Tonne

- Computerized

- Yes

- Automatic

- Fully Automatic

- Control System

- PLC based automatic control panel

- Power Source

- Electric

- Power Consumption

- 40-60 kW

- Storage Capacity

- 4x10 m (Aggregate Storage Bin)

- Hopper Capacity

- 800-2000 liters

- Hopper Quantity

- 4

- Conveyor Capacity

- 120 tons/hour

- Mixing Drum Speed

- 20 rpm

- Discharging Height

- 4.2 meters

- Voltage

- 415 V

- Dimension (L*W*H)

- 11800 x 2500 x 9000 mm

- Color

- Yellow and Grey

Inline Series Batching And Mixing Plant Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 3 Units Per Week

- Delivery Time

- 15 Days

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, Africa

- Main Domestic Market

- All India

- Certifications

- CE, ISO

About Inline Series Batching And Mixing Plant

Under the visionary observation of our adept professionals, this Inline Series Batching And Mixing Plant is manufactured by making use of quality approved components and modern technology. Used for mixing the materials like cement, sand and many others, the offered plant is known for its effective functionality, robust construction and long service life. Also, tested on diverse aspects, this Inline Series Batching And Mixing Plant is provided at industry leading rates to the clients.

Inline Mixing Plant Technical Features :

- PLC operated completely automatic control panel.

- Blade mixing technology with planetary gear-boxes.

- Electronic weighing system for better accuracy in design.

- Separate weighing system for cement and fly-ash.

- Italian screw feeder, to pour cement speedily

- Password locking facility

- Water and ad-mix pour by weight.

- Pneumatically weighing system for cement and fly-ash.

- Italian screw feeder to pour cement speedily.

- Password locking facility.

- Water and ad-mix pour by weight.

- Separate Weighting Belt Conveyor.

- Pneumatically operated gate for aggregate and sand.

- Italian vibrators.

- Tabulated print out system for each batch.

- No pit required only nominal civil work.

- Heat proof control cabin.

- Cement silo with vertical screw feeder (optional)

- Hydraulic discharge system.(For Pan Mixer)

- E-mail or SMS facility (optional)

This is very popular design in foreign countries. We are introducing this machinery in the following ranges:

Technical Specification:

| Control System | PLC |

| Discharge System | Hydraulic |

| Operation | Automatic |

| Chassis Material | Cast Iron |

| Model/Type | Inline Series |

| Brand/Make | AKONA |

Precision Mixing and Efficient Output

This batching plant combines advanced digital weighing and computerized controls to ensure precise aggregate, cement, and water measurements for every batch. The systems pan mixer operates at up to 20 rpm, capable of handling diverse batch volumes to meet high-demand construction timelines, delivering output rates between 30 and 60 m/hour.

Flexible Storage and Automated Operation

Featuring 4 inline bins with a combined storage capacity of 40 m and hoppers holding 800 to 2000 liters, all aggregates are stored and fed with maximum efficiency. Full automation powered by a PLC-based control system guarantees consistent mix quality and hassle-free operations, reducing manual intervention and improving productivity.

FAQs of Inline Series Batching And Mixing Plant:

Q: How does the digital load cell-based aggregate weighing system enhance batching accuracy?

A: The digital load cell-based system precisely measures aggregate quantities, minimizing errors and ensuring consistent mix ratios for high-quality concrete production.Q: What is the process for operating the Inline Series Batching And Mixing Plant?

A: Operation is fully automated via a PLC-based panel. Operators program batch parameters, and the system manages weighing, mixing, and discharge, with options for moisture adjustment and admixture dosing.Q: When is this batching plant most beneficial for construction projects?

A: It is ideal for projects that require frequent and sizable concrete batches, particularly where output capacity, speed, and precise mix control are essential, such as infrastructure or large-scale commercial builds.Q: Where can the Inline Series Batching And Mixing Plant be installed?

A: The plant is suitable for installation at construction sites with access to electricity and adequate space for its dimensions (11800 x 2500 x 9000 mm), typically at commercial or infrastructural project locations across India.Q: How does the included admixture dosing unit improve concrete quality?

A: The admixture dosing unit allows controlled addition of chemical additives, enhancing concrete properties like workability, setting time, and durability directly during the batching process.Q: What are the usage benefits of the fully automatic system and optional accessories?

A: Full automation ensures rapid, consistent production while optional features like moisture sensors and printout systems help monitor mix performance, maintain records, and adapt to site conditions, maximizing efficiency and quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Concrete Batching Plant Category

Pan Mixer Type Batching Plant

Price 1400000 INR / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : 1 to 20 Tonne

Power Source : Electric

Computerized : Yes

Power Consumption : 5 15 kW (approx.)

Concrete Batching Twin-Shaft Mixing Plant

Price 1400000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : 1 to 20 Tonne

Power Source : Electric

Computerized : Yes

Power Consumption : 60120 kW

Modular Concrete Batching Plant

Price 1400000 INR / Piece

Minimum Order Quantity : 1 Unit

Weight (kg) : 1 to 20 Tonne

Power Source : Electric

Computerized : Yes

Power Consumption : 60 85 kW

Batching and Mixing Plant

Price 1400000 INR / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : 1 to 20 Tonne

Power Source : Electric

Computerized : Yes

Power Consumption : 20 kW

Send Inquiry

Send Inquiry