Mobile Concrete Batching Plant

Price 1400000 INR/ Unit

Mobile Concrete Batching Plant Specification

- Product Type

- Mobile Concrete Batching Plant

- General Use

- MS

- Material

- Other

- Type

- Batching Plant

- Weight (kg)

- 1 to 20 Tonne

- Computerized

- Yes

- Automatic

- Automatic

- Control System

- PLC Control Panel

- Power Source

- Electric

- Power Consumption

- 60-80 kW

- Storage Capacity

- 30 m

- Hopper Capacity

- 4x6 m

- Hopper Quantity

- 4

- Conveyor Capacity

- 80 tons/hour

- Mixing Drum Speed

- 18 rpm

- Discharging Height

- 4.1 m

- Voltage

- 415 V

- Dimension (L*W*H)

- 12800x2400x4100 mm

- Color

- Yellow & Blue

- Chassis

- Heavy Duty

- Max Aggregate Size

- 80 mm

- Container Friendly

- Yes

- Water Tank Capacity

- 500 Liters

- Environment Compliance

- Dust-proof Design

- Batch Cycle Time

- 72 Seconds

- Aggregate Feeding Mode

- Belt Conveyor

- Mixing Type

- Twin Shaft Mixer

- Mobility

- Wheel Mounted

- Brand Name

- Standard

- Cement Weighing System

- Load Cell Based

- Suitable for Projects

- Construction Sites, Roadwork, Bridges

- Power Requirement Frequency

- 50 Hz

- Application Temperature

- -10°C to +50°C

Mobile Concrete Batching Plant Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 3 Units Per Week

- Delivery Time

- 15 Days

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, Africa

- Main Domestic Market

- All India

- Certifications

- CE, ISO

About Mobile Concrete Batching Plant

Mobile Concrete Batching Plant Features:

2) Easy maintenance

3) Excellent performance

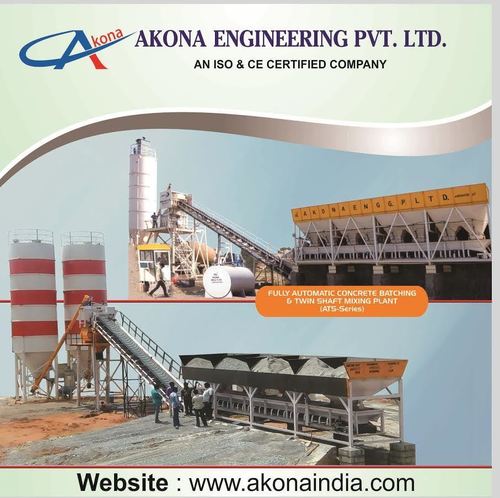

Advanced Mixing Technology for Superior Concrete Quality

This mobile batching plant uses a twin shaft mixer and belt conveyor system, providing consistent and thorough blending of aggregates. The automatic PLC control panel ensures precise batching, while the dust-proof enclosure supports compliance on environmentally sensitive sites. With a rapid batch cycle and large aggregate storage, this plant delivers high-quality concrete efficiently.

Engineered for Mobility and Versatility

Wheel mounted and easily containerized, this plant is designed for swift setup and relocation. Measuring 12800x2400x4100 mm and weighing between 1 to 20 tonnes, it suits projects requiring temporary or mobile concrete production facilities. The plant is ideal for construction sites, infrastructure projects, and bridgework.

Precision Weighing and Control System

The load cell-based cement weighing system ensures accurate measurement for each batch. Coupled with a PLC control panel and computerized operation, the plant delivers consistent results and reduces human error. Operators can monitor and adjust parameters to optimize mixing and resource utilization.

FAQs of Mobile Concrete Batching Plant:

Q: How does the twin shaft mixer improve concrete quality in this batching plant?

A: The twin shaft mixer in the Standard mobile batching plant provides vigorous and uniform mixing, ensuring that aggregates up to 80 mm are thoroughly blended. This results in consistently high-quality concrete with excellent strength and homogeneity for construction applications.Q: What is the process for relocating the wheel-mounted batching plant?

A: Relocating the wheel-mounted batching plant is straightforward due to its mobility features. The design allows for easy transportation and swift setup at different project sites, thanks to its heavy-duty chassis, container-friendly dimensions, and wheel-mount system.Q: When is it ideal to use this mobile concrete batching plant?

A: This plant is ideal for time-sensitive projects such as roadwork, bridge construction, and temporary site setups where rapid concrete batch cycles and flexibility are required. Its design allows efficient operation in varied climates and locations.Q: Where can this batching plant be deployed for optimal use?

A: The Standard mobile batching plant is best deployed at construction sites, infrastructure developments, roadwork zones, and bridge-building projects requiring quality concrete and versatile mobility.Q: What are the key benefits of the PLC controlled automatic batching system?

A: The automatic PLC control panel streamlines operations, improves batching accuracy, enables real-time monitoring, and minimizes manual intervention. This leads to better resource management, reduced errors, and enhanced productivity.Q: How is environmental compliance achieved with this batching plant?

A: The plant features a dust-proof design that helps control emissions and maintain clean work environments, supporting compliance with environmental regulations on site.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Concrete Batching Plant Category

Concrete Batching Plant With Drum Mixer

Price 280000 INR / Unit

Minimum Order Quantity : 1 Unit

Power Consumption : 50 400 Horsepower (HP)

Weight (kg) : 10 50 Tonne

Storage Capacity : 20000 50000 Kilogram(Kg)

Type : Concrete Mixing Plant, Mobile Concrete Batching Plant

Pan Mixer Type Batching Plant

Price 1400000 INR / Unit

Minimum Order Quantity : 1 Unit

Power Consumption : 5 15 kW (approx.)

Weight (kg) : 1 to 20 Tonne

Storage Capacity : 500 to 1000 liters

Type : Other, Batching Plant

Concrete Batching Twin-Shaft Mixing Plant

Price 1400000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Power Consumption : 60120 kW

Weight (kg) : 1 to 20 Tonne

Storage Capacity : 50200 Tons

Type : Other, Mixing Plant

Inline Series Batching And Mixing Plant

Price 1400000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Power Consumption : 4060 kW

Weight (kg) : 1 to 20 Tonne

Storage Capacity : 4x10 m (Aggregate Storage Bin)

Type : Other, Inline Series Batching and Mixing Plant

Send Inquiry

Send Inquiry